Productbeschrijving:

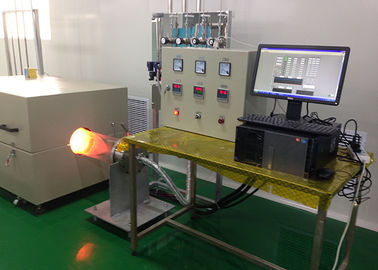

De industriële keramische oven is een geavanceerde verwarmingsoplossing die speciaal is ontworpen voor de veeleisende eisen van de keramische verwerkende industrie.Gemaakt met precisie en geavanceerde technologieDeze oven biedt uitzonderlijke prestaties voor het sinteren, gloeien en de warmtebehandeling van keramiek.De robuuste constructie en de innovatieve kenmerken maken het een onmisbare aanwinst voor fabrikanten die op zoek zijn naar betrouwbare en efficiënte warmteverwerkingsapparatuur.

De kern van de industriële keramische oven is het elektrische verwarmingselement van hoogwaardige siliciummolibdeenstaven.uniforme temperatuurverdeling, en uitstekende duurzaamheid, zelfs bij continue werking bij hoge temperaturen.die de levensduur van de oven aanzienlijk verlengt en de onderhoudskosten in de loop van de tijd vermindert.

Een van de opmerkelijke kenmerken van de industriële keramische oven is de veelzijdigheid in installatie en gebruik.aan de verschillende operationele behoeften en beperkingen van de werkruimte voldoenDe vaste optie is ideaal voor permanente installaties waar consistente en gecontroleerde verwarmingsprocessen essentieel zijn.waardoor de oven gemakkelijk binnen een installatie kan worden verplaatst of tussen locaties kan worden vervoerd, waardoor het geschikt is voor dynamische productieomgevingen of onderzoekslaboratoria.

De oven is speciaal ontworpen om te werken bij een maximale temperatuur van 900°C, waardoor deze zeer geschikt is voor de warmtebehandelingsprocessen die nodig zijn bij de keramische productie.Deze werktemperatuur zorgt ervoor dat de oven keramische materialen effectief kan sinterenBovendien vermindert het in de oven uitgevoerde gloeiproces de interne spanningen in keramische onderdelen.verbetering van hun structurele integriteit en prestaties bij eindtoepassingen.

De grootte van de kamers van de industriële keramische oven varieert van 600 mm tot 1200 mm breed en 200 mm tot 350 mm hoog.Deze ruime kamer maakt het mogelijk om verschillende keramische onderdelen en componenten te plaatsen, die voldoende ruimte biedt voor batchverwerking of voor grotere behandeling in één stuk.die van cruciaal belang is voor het bereiken van consistente en kwalitatief hoogwaardige resultaten bij keramische sinter- en gloeibewerkingen.

Duurzaamheid en veiligheid staan centraal in het ontwerp van de keramische oven.de oven behoudt een optimaal thermisch rendement en beschermt de gebruikers tegen overmatige blootstelling aan warmteDe in de oven geïntegreerde besturingssystemen zorgen voor een nauwkeurige temperatuurregulatie, programmeerbare verwarmingscycli en realtime monitoring.ervoor zorgen dat elk warmtebehandelingsproces voldoet aan strenge kwaliteitsnormen.

Bedrijven die gebruikmaken van de industriële keramische oven profiteren van verhoogde productiviteit, verbeterde materiaal eigenschappen en lagere bedrijfskosten.met een gewicht van niet meer dan 10 kgDeze oven levert een consistente en betrouwbare prestaties.De aanpassingsmogelijkheden voor zowel vaste als mobiele toepassingen vergroten de waarde ervan in verschillende productiesectoren.

Samengevat, de Industrial Ceramic Furnace onderscheidt zich als een high-performance, veelzijdige en betrouwbare oplossing voor keramische sintering, gluren en warmtebehandeling.Elektrische verwarmingselementen van siliciummolibdeenstaven, met een werkstemperatuur tot 900 °C, ondersteunt het een breed scala aan keramische verwerkingsbehoeften.De royale afmetingen van de kamer en de mogelijkheden voor vaste of mobiele configuraties maken het een praktische keuze voor verschillende industriële toepassingenInvesteren in deze industriële keramische oven betekent het verzekeren van superieure kwaliteit thermische verwerking mogelijkheden die efficiëntie en product excellentie te stimuleren.

Toepassingen:

De Yanyangtian-industrie-keramische oven, afkomstig uit China, is een hoogtemperatuuroven die is ontworpen om te voldoen aan de strenge eisen van verschillende industriële toepassingen.Bekend om zijn uitzonderlijke temperatuuruniformiteit van ± 5 °C binnen het constante temperatuurgebied, zorgt deze oven voor een precieze en constante verwarming, wat van cruciaal belang is voor processen die een strenge thermische controle vereisen.de industriële keramische oven biedt flexibele installatieopties om aan verschillende operationele behoeften te voldoen, waardoor het geschikt is voor zowel vaste productie-installaties als voor installaties die mobiliteit vereisen.

Deze industriële keramische oven wordt veel gebruikt in de keramische industrie voor het branden en sinteren van keramische producten.wanneer een nauwkeurige temperatuurregeling rechtstreeks van invloed is op de kwaliteit en duurzaamheid van de eindproductenDe modulaire structuur van de montageovens maakt het gemakkelijk aan te passen en te onderhouden.de industrie in staat te stellen haar productiecapaciteit te vergroten of de ovenconfiguratie aan te passen aan specifieke procesvereistenDe hoge elektrische vermogensspecificatie van niet meer dan 60 kW/380 V zorgt ervoor dat het efficiënt functioneert en tegelijkertijd de nodige thermische energie levert voor veeleisende keramische verwerkingswerkzaamheden.

Naast keramiek, vindt de Yanyangtian Industrial Ceramic Furnace toepassing in verschillende andere industriële scenario's zoals glasverwerking, metallurgie en materiaalonderzoek.de oven zorgt voor een gecontroleerde warmtebehandelingIn de metallurgische industrie worden deze ovens gebruikt voor warmtebehandeling, zoals gloeien, verharding,met een gewicht van niet meer dan 50 kg, met een precieze temperatuurregeling en een modulair ontwerp.onderzoekslaboratoria en industriële testfaciliteiten gebruiken de oven om hoge temperatuuromgevingen te simuleren voor materiaalanalyse en productontwikkeling.

Over het algemeen, de Yanyangtian industriële keramische oven valt uit als een veelzijdige, betrouwbare,en efficiënte oplossing voor industrieën die een hoge temperatuur verwerking met strikte temperatuur uniformiteitDe combinatie van geavanceerde functies, waaronder modulaire assemblage, flexibele draagbaarheid opties en robuuste vermogen specificaties,maakt het een onmisbaar hulpmiddel in moderne industriële verwarming en warmtebehandeling toepassingen.

Aanpassing:

Yanyangtian biedt op maat gemaakte industriële keramische oven oplossingen ontworpen om aan uw specifieke sintering, gloeien en warmtebehandeling behoeften van keramiek.We leveren industriële keramische ovens met een variabele kamergrootte., meestal 300 mm x 300 mm x 300 mm, waardoor optimale prestaties voor uw toepassingen worden gewaarborgd.

Onze industriële keramische oven aanpassingsdiensten omvatten opties voor stationaire of mobiele eenheden, zodat u de draagbaarheid kunt selecteren die het beste past bij uw operationele vereisten.Elke oven is voorzien van een 1-2 jaar fabrikant garantie, waardoor de betrouwbaarheid en de gemoedsrust van uw investering gegarandeerd zijn.

Of u nu specifieke specificaties nodig heeft voor de grootte van de kamer, het temperatuurbereik of de mobiliteit,Yanyangtian's Industrial Ceramic Furnace-aanpassingsdiensten leveren duurzame en efficiënte hoogtemperatuurovens die perfect aansluiten bij uw industriële keramische verwerkingsbehoeften.

Ondersteuning en diensten:

Onze industriële keramische oven wordt ondersteund door uitgebreide technische ondersteuning en diensten om optimale prestaties en levensduur te garanderen.routinematige onderhoudsregelingen, en hulp bij het oplossen van problemen om de stilstand te minimaliseren en de efficiëntie te maximaliseren.

Ons team van ervaren technici is beschikbaar voor ondersteuning ter plaatse en diagnostiek op afstand.

Er zijn opleidingen beschikbaar voor uw personeel om de veilige en effectieve werking van de oven te garanderen.Wij bieden op maat gemaakte servicecontracten aan om aan de unieke behoeften van uw industriële processen te voldoen..

Voor technische vragen of serviceverzoeken raadpleegt u de productdocumentatie of bezoekt u ons ondersteuningsportaal voor gedetailleerde handleidingen, veelgestelde vragen en instructievideo's.

Verpakking en verzending:

Onze industriële keramische oven is zorgvuldig verpakt om maximale bescherming te garanderen tijdens het transport.Elk apparaat wordt goed ingepakt met hoogwaardige schuimvulling en in een stevige houten kist geplaatst om schade door schokken of trillingen te voorkomen.

De verpakking is ontworpen om te kunnen weerstaan aan zware verzendomstandigheden en is duidelijk gemarkeerd met handhavingsaanwijzingen om een veilige levering te garanderen.

Voor de verzending maken wij gebruik van betrouwbare logistieke partners die gespecialiseerd zijn in het verwerken van zware industriële apparatuur.zorg voor tijdige en veilige levering naar uw faciliteit.

Bij aankomst dient u de verpakking te controleren op eventuele tekenen van beschadiging en onmiddellijk te melden als er problemen zijn.Ons team is toegewijd aan volledige ondersteuning tijdens het verzendproces om uw volledige tevredenheid te garanderen..

Vragen:

V1: Wat is de merknaam van deze industriële keramische oven?

A1: De industriële keramische oven wordt geproduceerd door Yanyangtian, een gerenommeerd merk dat bekend staat om zijn kwalitatieve industriële verwarmingsapparatuur.

V2: Waar wordt de Yanyangtian industriële keramische oven gemaakt?

A2: Deze industriële keramische oven is in China vervaardigd, zodat aan de strikte productiestandaarden wordt voldaan.

V3: Voor welke toepassingen is de Yanyangtian industriële keramische oven geschikt?

A3: De oven is ideaal voor keramisch branden, warmtebehandelingsprocessen, sinteren en andere industriële verwarmingstoepassingen die een nauwkeurige temperatuurregeling vereisen.

V4: Welk temperatuurbereik kan de Yanyangtian-industriële keramische oven bereiken?

A4: De oven kan hoge temperaturen bereiken, meestal tot 1300°C of hoger, geschikt voor verschillende keramische en industriële processen.

V5: Hoe wordt de temperatuur in de industriële keramische oven van Yanyangtian gecontroleerd?

A5: De oven beschikt over een geavanceerde digitale temperatuurregelaar die precieze temperatuurinstellingen en een uniforme warmteverdeling mogelijk maakt voor consistente resultaten.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!