Product Description:

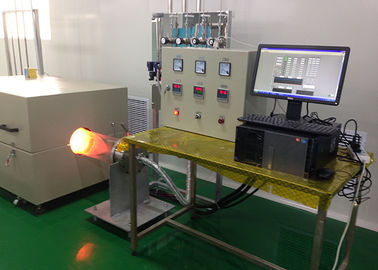

The Industrial Glass Furnace is a state-of-the-art solution designed to meet the demanding needs of modern glass production facilities. Specially engineered to handle various glass products, this furnace is optimized for efficiency, durability, and superior thermal performance. At its core, the furnace features a highly customizable Furnace Heat Chamber, allowing manufacturers to tailor the size and configuration precisely to their production requirements. This customization ensures that the furnace can accommodate a wide range of glass product types and batch sizes, enhancing operational flexibility and productivity.

Constructed from high-grade refractory bricks and robust steel, the Industrial Glass Furnace guarantees exceptional structural integrity and longevity. The refractory bricks are carefully selected for their excellent resistance to high temperatures and thermal shock, which is critical in maintaining the furnace’s performance over extended periods of continuous operation. The steel framework provides a solid foundation, ensuring stability and safety while supporting the intense thermal processes within the Furnace Heat Chamber.

One of the standout features of this Industrial Melting Furnace is its advanced insulation system, which utilizes a high-temperature fiber blanket. This insulation material is crucial in minimizing heat loss, thereby improving energy efficiency and reducing operational costs. The high-temperature fiber blanket effectively retains heat within the furnace, maintaining consistent melting temperatures and ensuring uniform glass quality. This efficient insulation also contributes to a safer working environment by reducing external surface temperatures and minimizing the risk of heat-related hazards.

The furnace operates on gas fuel, a choice that offers numerous advantages including cleaner combustion, precise temperature control, and cost-effectiveness. Gas fuel allows for rapid heating and consistent temperature maintenance within the Furnace Heat Chamber, which is essential for producing high-quality glass products. The ability to finely control the heat input helps in achieving optimal melting conditions, reducing defects in the final glass output and enhancing overall product quality.

Designed with versatility and performance in mind, the Industrial Glass Furnace is suitable for a variety of glass manufacturing applications, from flat glass to specialty glass products. Its customizable chamber size and advanced material composition make it an ideal choice for industries seeking to improve their melting processes while maintaining a sustainable and efficient operation. Whether operating in large-scale industrial plants or smaller production facilities, this furnace stands out as a reliable and efficient melting solution.

In summary, the Industrial Glass Furnace combines a customizable Furnace Heat Chamber, high-grade refractory bricks and steel construction, advanced high-temperature fiber blanket insulation, and efficient gas fuel operation to deliver superior melting performance. Its design ensures maximum energy retention and structural durability, making it an indispensable component in the glass manufacturing industry. By choosing this Industrial Melting Furnace, manufacturers can expect enhanced productivity, improved glass quality, and reduced operational costs, positioning their operations at the forefront of technological advancement in glass production.

Features:

-

Product Name: Industrial Glass Furnace

-

Furnace Type: Box

-

Application: Glass Industrial

-

Condition: New

-

Insulation Material: High-Temperature Fiber Blanket

-

Equipped with a highly efficient Furnace Heat Chamber for optimal thermal performance

-

Designed as an Electric Glass Furnace to ensure precise temperature control and energy efficiency

-

Serves as a reliable Industrial Melting Furnace for various glass production processes

Technical Parameters:

|

Product Name

|

Industrial Glass Furnace

|

|

Melting Rate

|

0.5-10 Tons Per Hour

|

|

Service

|

Engineering Overseas Service

|

|

Application

|

Glass Industrial

|

|

Chamber Size

|

Customized

|

|

Operating Temperature

|

Up To 1600°C

|

|

Furnace Type

|

Box

|

|

Temperature Uniformity

|

± 3 ℃ (9 Point Test)

|

|

Condition

|

New

|

|

Fuel Type

|

Gas

|

Applications:

The Yanyangtian Industrial Glass Furnace is a state-of-the-art Heat Treatment Furnace designed for various industrial glass production and processing applications. This high-performance Electric Glass Furnace offers exceptional melting rates ranging from 0.5 to 10 tons per hour, making it suitable for both small-scale and large-scale manufacturing operations. Built with high-grade refractory bricks and steel, the furnace ensures durability, energy efficiency, and consistent temperature control, which are critical for producing high-quality glass products.

Thanks to its customizable chamber size, the Yanyangtian Industrial Glass Furnace can be tailored to meet specific production requirements, enabling companies to optimize their processes and improve output. The product is CE and UL certified, guaranteeing compliance with international safety and quality standards. With a minimum order quantity of just 1 kg and negotiable pricing, this furnace offers flexibility and accessibility for various clients, from startups to established enterprises.

The furnace is ideally suited for industries involved in the manufacturing of flat glass, container glass, specialty glass, and other glass products requiring precise heat treatment. Its advanced electric heating technology ensures uniform temperature distribution and efficient energy consumption, making it a preferred choice for electric glass furnace applications. Furthermore, the Yanyangtian Industrial Glass Furnace supports engineering overseas service, providing customers worldwide with expert installation, maintenance, and technical support.

Packaging is handled carefully with containerized shipping to protect the furnace during transit, and the delivery time is optimized at approximately 10 days. Payment terms are based on T/T, facilitating secure and straightforward transactions. With a supply ability of 10 tons per year, Yanyangtian can accommodate consistent demand while maintaining high standards of quality and service.

In summary, the Yanyangtian Industrial Glass Furnace is an ideal solution for industries seeking a reliable, efficient, and customizable heat treatment furnace. Its advanced electric glass furnace technology, robust construction, and comprehensive service package make it a valuable asset in the glass manufacturing sector, ensuring enhanced productivity and superior glass quality across various application scenarios.

Customization:

Yanyangtian offers customized Industrial Glass Furnace solutions designed to meet the specific needs of your glass processing projects. Our Industrial Vacuum Furnace features a highly efficient Furnace Heat Chamber capable of operating at temperatures up to 1600°C, ensuring optimal glass quality and durability.

Certified with CE and UL standards, our furnaces guarantee safety and reliability for all industrial applications. With a temperature uniformity of ± 3 ℃ based on a 9-point test, the furnace provides consistent heating essential for precision glass processing machinery operations.

We supply our Industrial Glass Furnace with a minimum order quantity of 1kg, packaged securely in containers to ensure safe delivery. Our supply ability is 10 tons per year, with a delivery time of 10 days. Payment terms are based on TT, and prices are negotiable to suit your project requirements.

Additionally, Yanyangtian provides comprehensive engineering overseas service to support installation and maintenance, ensuring seamless integration with your existing glass processing machinery. Our product is ideal for manufacturing high-quality tableware and other glass products under new, advanced conditions.

Support and Services:

Our Industrial Glass Furnace product is backed by comprehensive technical support and services to ensure optimal performance and longevity. We offer expert installation guidance, routine maintenance schedules, and troubleshooting assistance to minimize downtime and enhance productivity. Our team of skilled technicians provides on-site support and remote diagnostics to quickly resolve any operational issues. Additionally, we supply genuine replacement parts and offer training sessions for your staff to operate and maintain the furnace safely and efficiently. Trust our dedicated support services to keep your Industrial Glass Furnace running smoothly and effectively.

Packing and Shipping:

Our Industrial Glass Furnace is carefully packaged using high-quality, durable materials to ensure maximum protection during transit. Each unit is securely wrapped with industrial-grade foam padding and enclosed in a custom-fitted wooden crate to prevent any damage from shocks or vibrations.

The packaging is designed to withstand harsh shipping conditions and is clearly labeled with handling instructions and safety warnings. All necessary components and accessories are packed separately within the crate and securely fastened to avoid movement.

For shipping, we coordinate with trusted logistics partners experienced in handling heavy and sensitive industrial equipment. The furnace is transported using specialized vehicles equipped with lifting and securing mechanisms to guarantee safe delivery to your facility.

Upon arrival, our team offers support for unloading and installation to ensure your Industrial Glass Furnace is set up correctly and ready for operation.

FAQ:

Q1: What certifications does the Yanyangtian Industrial Glass Furnace have?

A1: The Yanyangtian Industrial Glass Furnace is CE and UL certified, ensuring it meets international safety and quality standards.

Q2: What is the minimum order quantity for the Industrial Glass Furnace?

A2: The minimum order quantity for the Yanyangtian Industrial Glass Furnace is 1 kilogram.

Q3: How is the Yanyangtian Industrial Glass Furnace packaged for delivery?

A3: The Industrial Glass Furnace is securely packaged in containers to ensure safe transportation.

Q4: What is the typical delivery time for an order of the Industrial Glass Furnace?

A4: The standard delivery time for the Yanyangtian Industrial Glass Furnace is 10 days after order confirmation.

Q5: What payment terms are accepted for purchasing the Industrial Glass Furnace?

A5: Payment for the Yanyangtian Industrial Glass Furnace is accepted via T/T (Telegraphic Transfer).

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!