Product Description:

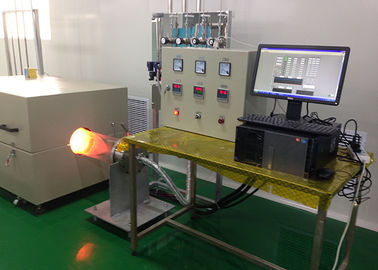

The Industrial Glass Furnace is a state-of-the-art solution designed specifically for the production of high-quality glass products, including exquisite tableware. Engineered to meet the rigorous demands of modern glass manufacturing, this furnace operates on gas fuel, ensuring efficient and consistent heating performance. Its advanced design incorporates a Furnace Heat Chamber optimized for uniform temperature distribution, which is critical in achieving superior glass melting and forming.

One of the standout features of this Industrial Glass Furnace is its impressive melting rate, ranging from 0.5 to 10 tons per hour. This flexibility allows manufacturers to scale their production according to market needs, whether producing small batches of specialized glassware or large volumes of standard tableware. The furnace’s ability to maintain steady and high temperatures within the Furnace Heat Chamber ensures that the glass melts evenly, reducing defects and enhancing product quality.

Although this furnace operates primarily on gas, it integrates principles found in Electric Glass Furnace technology to optimize energy efficiency and temperature control. This hybrid approach leverages the benefits of gas heating while incorporating precise temperature monitoring and regulation systems that are characteristic of electric furnace designs. As a result, the furnace achieves superior thermal stability and energy savings, making it an environmentally friendly choice for industrial glass production.

Moreover, the Industrial Glass Furnace is designed with the latest advancements in vacuum technology, making it compatible with Industrial Vacuum Furnace applications. This feature allows manufacturers to conduct glass melting under controlled atmospheric conditions, which is essential for producing specialized glass products with enhanced clarity, strength, and purity. The vacuum environment minimizes oxidation and contamination, elevating the overall quality of the tableware produced.

Every unit of the Industrial Glass Furnace is brand new, incorporating cutting-edge materials and manufacturing techniques to ensure longevity, safety, and reliability. Its robust construction withstands the intense conditions within the Furnace Heat Chamber, providing consistent performance over extended operational cycles. Maintenance is streamlined through intuitive design elements, reducing downtime and operational costs.

In summary, the Industrial Glass Furnace is an indispensable asset for any glass production facility aiming to produce premium tableware with precision and efficiency. Its gas-fueled operation, combined with features derived from Electric Glass Furnace technology and compatibility with Industrial Vacuum Furnace processes, delivers unmatched versatility and performance. With a melting rate adaptable from 0.5 to 10 tons per hour, this furnace meets diverse production demands, ensuring manufacturers can respond dynamically to changing market requirements while maintaining exceptional product standards.

Investing in this new Industrial Glass Furnace means embracing innovation, quality, and efficiency in glass manufacturing. It stands as a testament to modern engineering, blending traditional gas fuel advantages with advanced furnace technologies to produce superior glass products that meet the highest industry standards.

Features:

-

Product Name: Industrial Glass Furnace

-

Condition: New

-

Fuel Type: Natural Gas, Oil, Electricity, Coal

-

Temperature Uniformity: ± 3 ℃ (9 Point Test)

-

Insulation Material: High-Temperature Fiber Blanket

-

Designed for Industrial Melting Furnace applications

-

Equipped with a durable Furnace Heat Chamber

-

Ideal for producing high-quality tableware

-

Efficient Industrial Melting Furnace ensuring consistent performance

Technical Parameters:

|

Product Name

|

Industrial Glass Furnace

|

|

Material

|

High-grade Refractory Bricks And Steel

|

|

Product

|

Tableware

|

|

Insulation Material

|

High-Temperature Fiber Blanket

|

|

Kind Of Glass

|

Glass Product

|

|

Temperature Uniformity

|

± 3 ℃ (9 Point Test)

|

|

Melting Rate

|

0.5-10 Tons Per Hour

|

|

Condition

|

New

|

|

Fuel Type

|

Gas

|

|

Operating Temperature

|

Up To 1600°C

|

Applications:

The Yanyangtian Industrial Glass Furnace is a highly efficient and reliable Industrial Melting Furnace designed specifically for the glass industry. With a robust box furnace design and the capability to operate at temperatures up to 1600°C, this Electric Glass Furnace is ideal for melting and processing various types of glass materials, including tableware production. Its industrial-grade construction ensures consistent melting rates ranging from 0.5 to 10 tons per hour, catering to both small-scale and large-scale manufacturing needs.

This Industrial Melting Furnace is certified with CE and UL standards, guaranteeing safety, quality, and performance. Yanyangtian’s furnace is packaged securely in containers to ensure safe delivery and comes with flexible payment terms via T/T, making it convenient for international buyers. The supply ability of 10 tons per year and a minimum order quantity of 1kg allow for tailored orders that suit different production demands. The delivery time of approximately 10 days further supports efficient production scheduling.

Application occasions for the Yanyangtian Industrial Glass Furnace span various industrial glass manufacturing scenarios. It is perfectly suited for factories specializing in tableware glass production, where precise temperature control and stable melting rates are critical to achieving high-quality glass products. Additionally, this furnace is ideal for research and development facilities working on innovative glass materials due to its advanced electric heating technology and controllable operating environment.

In industrial settings where reliable and continuous melting operations are essential, such as large glass manufacturing plants and specialized glass processing workshops, the Yanyangtian Electric Glass Furnace excels by providing consistent performance and energy efficiency. Its box furnace type design facilitates easy loading and unloading of raw materials and molten glass, enhancing operational workflow.

Overall, the Yanyangtian Industrial Melting Furnace stands out as a versatile and dependable solution for diverse glass industrial applications, including the production of tableware and other specialized glass products. Whether for new installations or upgrading existing melting equipment, this furnace offers a competitive price with negotiable terms, making it an excellent investment for businesses aiming to optimize their glass melting processes.

Customization:

Yanyangtian offers customizable Industrial Glass Furnace solutions designed to meet your specific glass processing machinery needs. Our Industrial Glass Furnace features a highly efficient Furnace Heat Chamber constructed with premium High-Temperature Fiber Blanket insulation material, ensuring optimal thermal performance and energy savings.

With a melting rate ranging from 0.5 to 10 tons per hour, our furnace is ideal for various industrial glass production scales. The furnace operates on gas fuel, providing a clean and controllable heat source within the Furnace Heat Chamber for consistent glass melting quality.

Certified with CE and UL standards, the Industrial Glass Furnace guarantees safety and reliability. We accept minimum orders starting from 1kg, with pricing negotiable depending on customization and order volume. Packaging is securely handled in containers to ensure safe delivery, with a typical delivery time of 10 days.

We support flexible payment terms including T/T and maintain a supply ability of 10 tons per year. Additionally, Yanyangtian provides overseas engineering services to assist with installation, commissioning, and maintenance of the Industrial Glass Furnace, ensuring smooth integration into your glass processing machinery operations.

Support and Services:

Our Industrial Glass Furnace product is backed by comprehensive technical support and services designed to ensure optimal performance and longevity. Our team of experts provides installation guidance, routine maintenance schedules, and troubleshooting assistance to minimize downtime and enhance productivity.

We offer detailed user manuals and operation training to help your staff operate the furnace safely and efficiently. Additionally, our service packages include regular inspections, parts replacement, and system upgrades tailored to your specific operational needs.

For any technical issues, our support team is ready to provide prompt remote assistance or on-site service visits to resolve problems quickly. We are committed to delivering reliable support that maximizes your investment and keeps your industrial glass furnace running at peak performance.

Packing and Shipping:

Our Industrial Glass Furnace is carefully packaged to ensure maximum protection during transit. Each unit is securely wrapped with industrial-grade protective materials and placed in a custom-designed wooden crate to prevent any damage from shocks or vibrations. The packaging is reinforced with metal straps and cushioning to safeguard sensitive components.

For shipping, we coordinate with trusted logistics partners experienced in handling heavy and delicate industrial equipment. The furnace is loaded using specialized machinery to guarantee safe handling. We offer various shipping options including sea freight, air freight, and land transport to meet your delivery requirements. Upon dispatch, you will receive detailed tracking information and estimated delivery timelines.

Our packaging and shipping processes comply with international standards to ensure your Industrial Glass Furnace arrives in perfect working condition and ready for installation.

FAQ:

Q1: What is the brand and model of the Industrial Glass Furnace?

A1: The Industrial Glass Furnace is manufactured by Yanyangtian and the model number is Industrial Glass Furnace.

Q2: What certifications does the Industrial Glass Furnace have?

A2: This product is certified with CE and UL certifications, ensuring compliance with safety and quality standards.

Q3: What is the minimum order quantity for the Industrial Glass Furnace?

A3: The minimum order quantity is 1 kilogram.

Q4: How is the Industrial Glass Furnace packaged and what is the typical delivery time?

A4: The furnace is packaged in a container for secure shipping, and the typical delivery time is 10 days.

Q5: What are the payment terms and supply ability for this product?

A5: The payment terms are T/T (telegraphic transfer), and the supply ability is 10 tons per year. The price is negotiable based on order quantity and specifications.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!